Drilling portals / Double place

SE 345 / SE 342 / SE 347 / SE 327

This series of double place machining centres are characterised by high efficiency in the machining of workpieces.

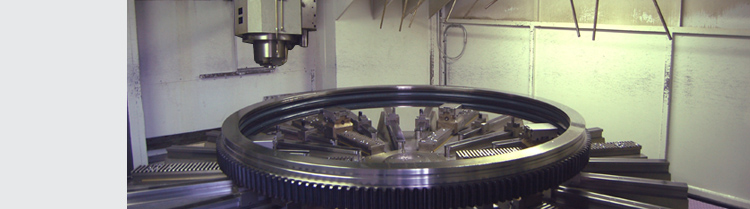

Made for drilling, tapping and milling tasks on workpieces in the production of large rolling bearings with two independent vertical work spindles on a rigidly constructed drilling portal.

This is achieved by the stable construction of the portal with two vertical machining units which are independent of each other. All drives of the portal's Y and Z axes are highly dynamic and equipped for robust machining. This machining centre is equipped with two slides for workpiece take up which can be moved independently of each other. These slides form the X axis and can both be moved into the work area for machining while the other slide moves to the setup place outside the machine for loading and unloading. In this way, even large workpieces are changed during machining times.

For the machining of round workpieces, these slides can also be equipped with an additional rotary axis and a collet chuck for workpiece holding.

One tool magazine is assigned to each machining unit at the portal's lateral columns. This tool magazine is in the form of a plate magazine with up to 36 places for the HSK100 tool taper. An angular drill head can be used which makes it possible to perform drilling, tapping and milling tasks for both exterior and interior machining of, for example, rolling bearing rings.